ABC Corporation

47 Village Court

Hazlet, NJ 07730

United States

ph: 732-888-1600

fax: 732-888-7520

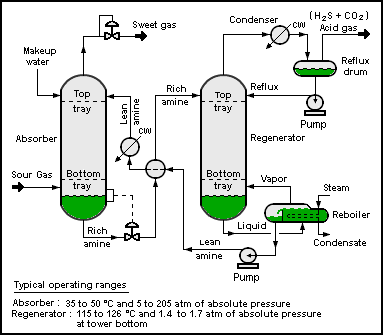

Amine purification

Gases containing H2S or both H2S and CO2 are commonly referred to as sour gases. The most commonly used amines in industrial plants are the alcohol amines MEA, DEA, and MDEA

There are many different amines used in gas treating

Amines are also used in many oil refineries to remove sour gases from liquid hydrocarbons such as liquefied petroleum gas (LPG)

The services provided are:

Supply of packages for:

The corrosion rate in all the alkanolamines seems to have similar sensitivity to HSS levels. The HSS interfere with the normally occurring H2S passivation of the carbon steel. Removing the HSS and maintaining them at low levels has not only reduced corrosion and the fouling caused by FeS, but has reduced operational upsets common to amine systems.

Maintaining low levels of Heat Stable Salts will maintain high purity amine solution and provide stable amine system performance. These benefits can result in the following:

Lower operating cost for the amine unit (less amine losses, lower filter change-out cost, less corrosion, lower maintenance cost, and lower steam cost)

Refiners experience increased throughput of sour crude by continuously maintaining

low concentrations of heat stable salts,hydrocarbons and solids, utilising an entirely onsite-regenerable amine purification system.

This continuous purification has been responsible for reducing the frequency and magnitude of

amine system operational problems, reducing maintenance costs, and facilitating the increased throughput of sour crude and hydrocarbon products.

With Amine Purification System using advanced exchange technology, continuously removes Heat Stable Salts (HSS) from amine solutions. Continuous removal of HSS allows for consistent, optimal performance of amine units with minimal operator attention required. Low HSS content dramatically reduces corrosion, thereby extending the life of process equipment and reducing maintenance and filter replacement requirements

At ABC We

We assist plant technicians in order to:

Copyright : ABC Corporation

47 Village Court

Hazlet, NJ 07730

United States

ph: 732-888-1600

fax: 732-888-7520